You Are Here:

Home

Industrial Valves

Top entry & Side entry Ball Valve

API 6D Pipeline Rising Stem Orbit Ball Valve

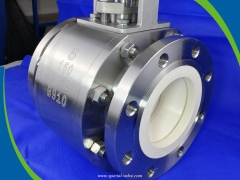

API 6D Pipeline Rising Stem Orbit Ball Valve

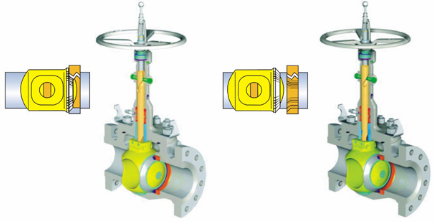

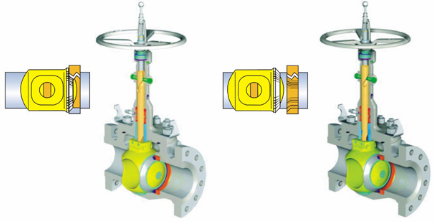

The

SV API 6D pipeline rising stem orbit ball valve adopts special stem to

make the ball rotate after separated from valve seat so that there is no

abrasion between ball and seat when operate the valve. Therefore it has much

lower operate torque and longer service life. It is

suitable for harsh service containing solid particle, sand, short fiber, pulp,

slurry etc. and high speed fluid which erode the ball and seat hardly.

The

SV top entry orbit ball valve also adopts top entry design to make the

maintenance can be made online without dismantling from the pipeline.

Inquiry Now

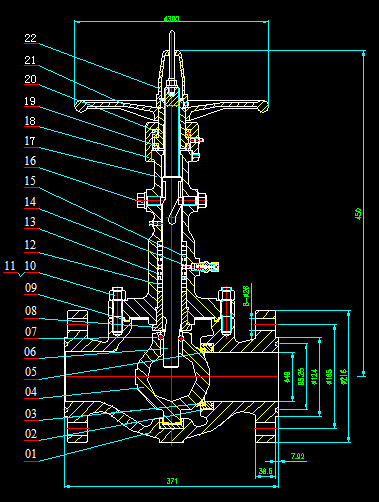

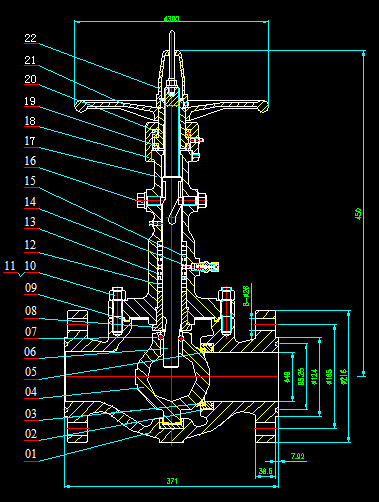

- The Ball of the SV pipeline orbit ball valve rotates after separated from seat

without any abrasion between ball and seat and solve the seat abrasion problem

of traditional ball valve, gate valve and plug valve;

- The SV API 6D orbit ball valve adopts single seat design to ensure bidirectional seal with

zero leakage and solves the problem of pressure increased in the cavity of

valve with double seats;

- Much longer serve life

and less breakdown time than traditional ball valve, gate valve, plug valve duo

to no abrasion between ball and seat;

- Much lower operate torque

duo to no abrasion between ball and seat, except for large size valve, small

handwheel is enough to operate the valve, and gearbox is no need;

- Best flow characteristic

with high Cv value minimizes the corrosion problem;

- Top entry design realizes

maintenance online and reduces breakdown time;

- When the ball separated

from the seat, the fluid can pass through completely and wash out the residue

bonded on the ball surface by 360° around

to achieve self-cleaning and reduces the impact on part of the seat by high

speed fluid;

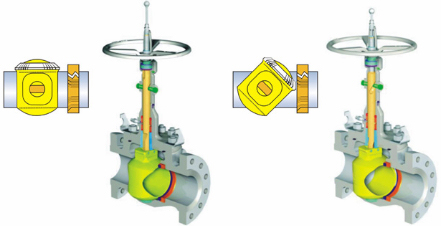

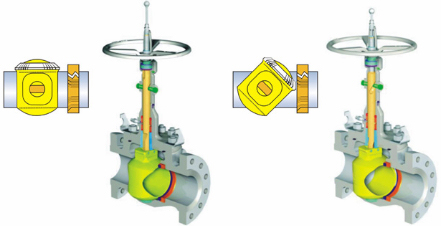

- The stem guide groove and

double guide pins control the rising, falling and rotating of stem and the

bevel at the bottom of stem can supply mechanical wedge force to press the ball

to the seat to achieve tight seal without influence by pressure difference of

pipeline;

- Ball sealing face is

overlaid by Nickel-based alloy, Hastelloy or other alloy to ensure the

tightness and service life in the harshest working condition;

- Fire safe, automatic

anti-static and anti-blowout stem design;

- When turns the handwheel

anticlockwise, the stem rises and the ball separates from seat first and then

rotates by 90°without abrasion until full opening position while the stem is

lifted to the highest position;

- When turns the handwheel clockwise, the stem falls and the ball rotates by 90° without abrasion until full closing position. Then keep on turning the handwheel for a few rounds, the bevel at the bottom of stem can press the ball to the seat tightly to achieve reliable seal.

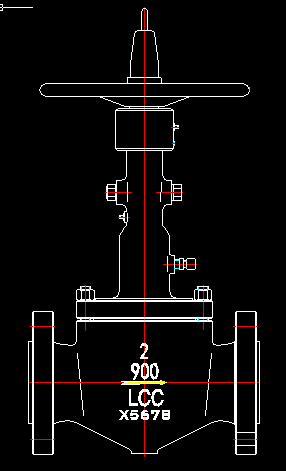

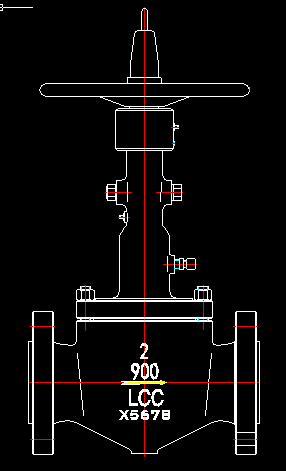

Product range:

- Size: 1''~28''

- Pressure

rating: Class 150~1500

- End connection:

RF, RTJ, BW

- Body materials: Carbon

steel A105, WCB, WCC, WC6, WC9, C12A; Low temperature steel LF2, LF3, LCB, LCC;

Stainless steel CF8, CF8M, CF3M, CF8C, F304, F316, F304L, F316L,F316Ti; Duplex

stainless steel 4A, 5A, F51, F53,904L; Super duplex stainless steel F55 etc.

- Ball materials:

A105 overlaid stellite or Ni alloy, LF2 overlaid stellite or Ni alloy, F304

overlaid stellite or Ni alloy, F316 overlaid stellite or Ni alloy etc.

- Seat materials:

A105 overlaid stellite or Ni alloy, LF2 overlaid stellite or Ni alloy, F304

overlaid stellite or Ni alloy, F316 overlaid stellite or Ni alloy etc.

- Operation: Bare

stem, Wrench, gear, electric, pneumatic.

Technical

standards:

- Design: API 6D

- Face to Face:

API 6D

- BW ends: ASME

B16.25, ASME B31.8

- Flanged ends:

ASME B16.5, ASME B16.47

- Wall thickness:

ASME B16.34

- Fireproof test:

API 607, API 6FA

- Test and

inspection: API 598, API 6D

- Pressure and

temperature rating: ASME B16.34

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder