Applications:

Coal

fired power plants:

Lime

slurry and gypsum slurry process water with high chlorides and solids content

in flue gas desulphurisation (FGD) system;

Steel

works:

Ore,

coke, metallurgy dust;

Blast

furnace coal powder injection;

Electric

arc furnace carbon powder injection;

Raw iron

desulphurisation with additives of CaC, MgO2 etc;

Mining:

Alumina

powder;

Splitting

of ore with H2SO4;

Copper

residues in suspension;

Concentrated

copper slurry;

Pneumatic

conveying of copper powder;

Similar

applications for zinc, nickel and other noble metals;

Polysililcon:

Si3Cl4,

TCS, raw silicon;

Splitting

of silicon with acids;

Conveying

of silicon powder;

Pneumatic

conveying:

All types

of dry bulk material (quartz, ash, fiber, glass, cement, PP pellet etc.);

Paper

& Pulp/dye works:

Kaoflin,

bentonite, fillers, dyes, bleachers, talcum, pulp residue, lime suspension,

MgO2, green liquor, wood particles in suspension;

Fertilizer:

Ammonium

nitrate slurry;

Phosphoric

acid with solids;

Washing

water with hydrofluoric acid content;

Waste

incineration plants:

HCl –

prewashers;

Limestone

suspension for pH regeneration;

Corrosive

washing water (HF loaded);

Petrochemistry:

Aluminium

oxide powder as the catalyst;

Pigments:

TiO2 suspension, Ti3Cl4, H2SO4+TiO2, FeCl2 etc.

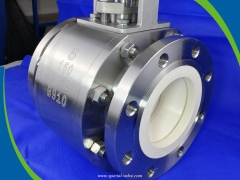

Product range:

Size: DN15~DN300 1/2’’ ~12’’

Pressure rating:

PN16—PN100 150lbs—600lbs

End connection: Flanged

RF RTJ BW

Body materials: A105

F304 F316 lined with Al2O3 ceramic

Seat materials:

Al2O3 ceramic

Ball materials:

ZrO2 ceramic

Technical

standards:

Design: ASME

B16.34

Face to Face: ASME

B16.10

Flanged ends: ANSI

B16.5 EN1092-1

Test & Inspection: API598

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder