Working principle:

1. Solid wastes contained in wastewater enter the HC non screen drum channel sewage grinder through open channel.

2. Double shaft blades shred the solid wastes by rotating in opposite direction.

3. Solid wastes are reduced to 6 mm-12 mm tiny particles without threat to downstream equipments and pass through the grinder.

Main Components:

Housing:

Housing:

Sturdy and durable, ASTM A536 ductile cast iron

Shaft:

ANSI 4140 heat treated ally steel with surface harden;

Connected with cutters through six-slot spline.

Double shaft blades:

Low rotating speed, high torque, powerful, low noise.

Cutters and spacers:

ANSI 4130 alloy steel with hardened surface, 45-55 HRC hardness;

Overlaid with Titanium is available;

Customize cutters with various construction and teeth number to meet different applications.

Mechanical seal assembly:

Tungsten carbide surface with Buna-N seal;

Pressure value up to 6.3 kg/cm².

Elastic coupling:

Shock absorbing and easy maintenance.

Motor:

Dry & wet motor with IP 55 is available;

Submersible and anti-explosive IP 68 for use under water is available.

Planetary gear reducer:

Strong anti-shock ability.

Side rails:

Increases flow capacity and decreases head loss;

Guides solid wastes into the cutting area.

Installation slot:

Easy and flexible installation cooperated with stainless steel installation frame, little or no civil work needed.

Products

Products

Industries

Industries

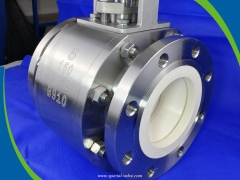

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder