Ceramic tile lined pipe with stud welding is developed for high temperature applications. Ceramic tile install on the pipe surface with glue and the tile has a hole in the middle and then stud weld the tile with steel. It is very well fixed.

Extreme wear resistant: High hardness ceramic, Rockwell hardness above HRA86, prolong the service life time at least 10 times.

Extreme shock resistant(key important): Using the formula which won the third prize of

national scientific and technological progress, fine grinding processing powder. Unique crystal

growth control technology, so that the ceramic to obtain the ideal microstructure of the

mechanical properties;

Protect from fall off (key important): Each ceramic tile was stud welded on the steel, and

also lined with adhesive. Double installation method made sure the ceramic will not fall off.

Professional welding: Use the professional stud welding technology.

High temperature resistant: Can be long-term operation at 0℃-500℃, can meet the requirement

of general feeding system.

Products

Products

Industries

Industries

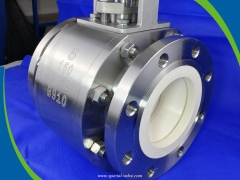

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder