Main Components:

Automatic belt tension seat: The motor is installed on a

belt tension supporting seat, which can adjust the motor position to reach the

preset tension, no need manual adjusting.

Pusher: The

hydraulic pusher pushes materials to the rotor repeatedly for shredding.

Screen: Various size and shape

of screens make the oversize particles shredded again.

Rotor: Various

rotor configurations are available for shredding wide range of materials. The

four edges of rotor can be used in turn to extend the service life by three

times.

Shock absorber: Shock absorber protects the single shaft shredder and its spare parts from damage during shredding. Equipped with micro

relay, the shredder can be shut down immediately when there is a sudden

overloading.

Reducer: Hardened gear, safe and stable,

equipped with water cooling function.

Bearing seat: Installed externally can effectively

avoid dust entering into the bearing seat. Equipped with lubricating nipple.

Hydraulic system: Pressure and flow rate can

be adjusted in according with the material type.

PLC control system: With Siemens programmed

control system, the single shaft shredder can be set to start, stop, and reverse automatically and protected from overloading and jamming.

Applications:

Plastics : plastic film, woven bag, baled PET/ HDPE & LDPE/ PP/ HIPS/ PS plastic pellets, plastic barrel, plastic pipes, plastic board, foam, MRF residuals, plastic lump, fiber, high strength engineering plastic

Textile: carpet, mattress, old clothes etc.

Wood: timber, tree root, wood board, plywood, railroad tires etc.

Light metal: can, aluminum scraps, wire, cable, tube

Other solid waste: paper, rubber, municipal solid waste, RDF (Reuse derive fuel), medical waste, industrial waste, hazardous waste, SRF (Solid Recovered Fuel), MRF (Materials Recovery Facility)

Products

Products

Industries

Industries

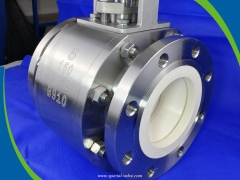

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder