You Are Here:

Home

Industrial Valves

Top entry & Side entry Ball Valve

API Side Entry Cast Steel Trunnion Mounted Ball Valve

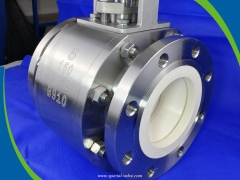

API Side Entry Cast Steel Trunnion Mounted Ball Valve

The

SV API side entry cast steel trunnion mounted ball valve has a

trunnion mounted ball supported by two floating seats.

The two floating seats

are movable and self-tightening with spring loaded under the seats.

The pressure of media

will push the two floating seats seal ring at both ends to attach the ball’s

surface tightly to ensure bidirectional reliable sealing.

The pressure of media

from ball is all transferred to the bearings not to the seats. The SV cast steel trunnion mounted ball valve

is suitable for large size and high pressure working condition.

Inquiry Now

- The SV high pressure cast steel trunnion

mounted ball valve has trunnion ball supported by upper and lower bearing to

reduce the friction between ball and seat so that the operate torque is small

for easy operation;

- Spring

loaded seat is self-tightening to ensure reliable tight seal;

- Cavity

pressure self relief when spring loaded single piston effect seat structure;

- Double

block and bleed for residue discharge and pressure relief;

- Emergency

sealant injection valve as

subsidiary sealing device;

- The SV split body cast steel trunnion

mounted ball valve can be divided into two piece split body and three piece split

body;

- The

two piece and three piece body is connected by bolts and nuts;

- Soft

seal structure and metal to metal seal structure;

- Designed

according to API or DIN standards;

- Full

bore and reduced bore structure;

- Optional

extended stem or extended bonnet;

- Optional

bare stem with ISO 5211 top flange;

- Fire

safe, anti-static and anti-blowout stem design.

Product range:

- Size: 2"~56" (DN50~1400)

- Pressure rating:

Class 150~2500 (PN16~PN420)

- End connection:

RF, RTJ, BW

- Body materials: Carbon

steel WCB/1.0619, Low temperature steel LCB/1.1156, Stainless steel CF8/1.4308,

CF3/1.4306, CF8M/1.4408, CF3M/1.4404, CF8C/1.4552, Duplex stainless steel UNS

S31803/2205/4A, UNS S32207; N08094/1.4539 etc.

- Ball materials:

A105+ENP, F304, F316, F304L, F316L, F51, F53, F55, 904L etc.;

- Seat materials:

PTFE, RPTFE, NYLON, DEVLON, PEEK, PPL, FKM or metal to metal seal etc.

- Operation: Bare

stem, wrench, gear, electric, pneumatic, electro-hydraulic, gas over oil actuator

Technical

standards:

- Design: API6D, ASME

B16.34, DIN 3357-1,EN12516-1

- Face to Face: ASME

B16.10, DIN 3202F1/F4/F5/F17/F18

- BW ends: ASME

B16.25, ASME B31.8, EN12627

- Flanged ends:

ASME B16.5, ASME B16.47, EN1092

- Wall thickness:

ASME B16.34

- Fireproof test:

API 607, API 6FA

- Test and

inspection: API 598, API 6D, DIN3230/3,EN12266

- Pressure and

temperature rating: ASME B16.34

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder